PROBLEM

Develop and fabricate a rate compatible manufacturing solution for Zone 5 Technologies, LLC to build the complex geometry, carbon fiber fuselage for its CLEAVER (Cargo Launch Expendable Air Vehicle with Extended Range) platform.

OPPORTUNITY

Create a fuselage composite solution to manufacture this complex geometry, fuselage, focusing on dry carbon fiber and epoxy resin infusion with novel manufacturing methods, to ensure ease of assembly, quality, and aggressive cost targets are met.

SOLUTION

Hawthorn Composites created a Smart Tooling, Resin Transfer Molding (RTM) solution that created a two piece fuselage with overlapping flanges for assembly after population, that was initially used by Zone 5. The solution was then modified, based on Zone 5’s feedback on how to improve ease of population and assembly, to a Vacuum Assisted Resin Transfer Molding (VARTM) solution that produced an upper fuselage composite nose and a complete lower composite fuselage.

FUSELAGE COMPOSITE SOLUTION A

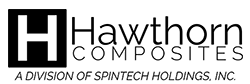

Hawthorn Composites worked with Zone 5 Technologies to develop the initial process, whereby the entire fuselage (nose, main body and tail) was manufactured as a single piece that could be separated, creating overlapping flanges for reassembly and fastening.

This fuselage used a custom Smart Tool that was initially laid up by hand to create local build-up with +/- 0° QISO™ Heavy carbon fabric from A&P Technology. Two pieces of Rohacell® core were installed and stabilized. Then the Smart Tool, with the buildup plies and core, was shipped to A&P Technology for over-braiding. Additively manufactured inserts were installed on the Smart Tool to modify the geometry of the nose and tail section to enable the entire over-braid to be installed on the Smart Tool using a single braiding machine. The Smart Tool and inserts were over-braided and once complete, the inserts were removed and pie cuts were taken out of the nose and tail, allowing the braided preform to be closed on the nose and tail geometries. Upon return, the laid-up Smart Tool was placed into an RTM mold for epoxy resin infusion and cure. Once above its activation temperature, the Smart Tool was inflated both during and after resin infusion, to ensure full compaction of the laminate and elimination of gasses during cure.

Once cured and while still hot, the RTM mold was opened and the part, with the Smart Tool still inside, was extracted. The Smart Tool, while in its hot, elastic state, was then simply and easily removed from the cured fuselage. The cured fuselage was then installed into a trim/drill fixture and nut plate holes were match drilled into the nose/main body and tail/main body. A control depth cut was performed to expose a laid up, co-cured 0.020” thick piece of Polytetrafluoroethylene (PTFE) that allowed for the separation of the nose/main body from the tail/main body. Once cut, the nose and tail were removed from the main body and the PTFE film was removed, leaving a match drilled assembly set of holes and a 0.020” thickness bond line for reattachment, after the population and integration of internal and external components.

(left) Overbraiding Process and (right) the final product

FUSELAGE COMPOSITE SOLUTION B

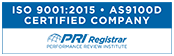

Through design iterations that enable reduced assembly and integration times for Zone 5, the manufacturing solution evolved to manufacture separate upper and lower fuselage sections. Smart Tooling was eliminated, as the complex geometry, composite fuselage was no longer being made in one piece. The upper fuselage was also modified to use an aluminum wing root section instead of composite. At low-volume production, the aluminum wing root provided a more robust structural tie-in for the wings. At higher volume production, it is expected the wing root interface will return to composite in order to lower the cost and increase rate compatibility.

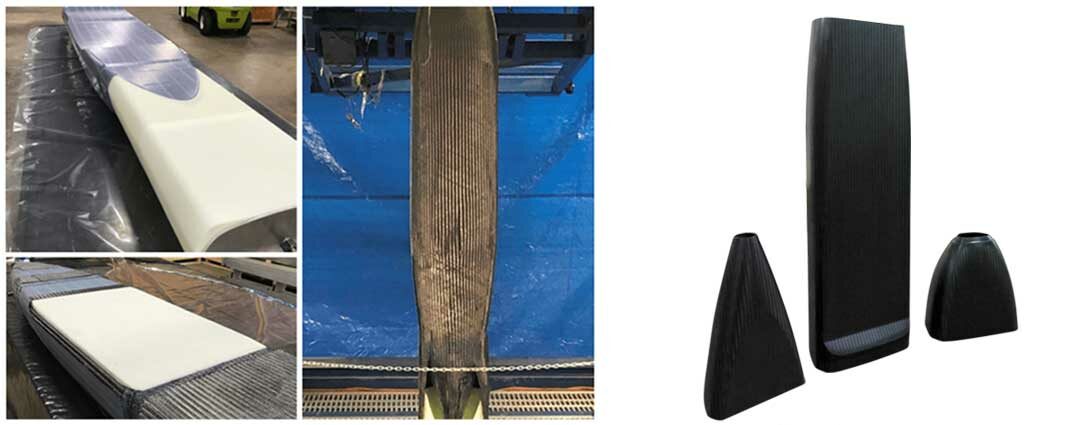

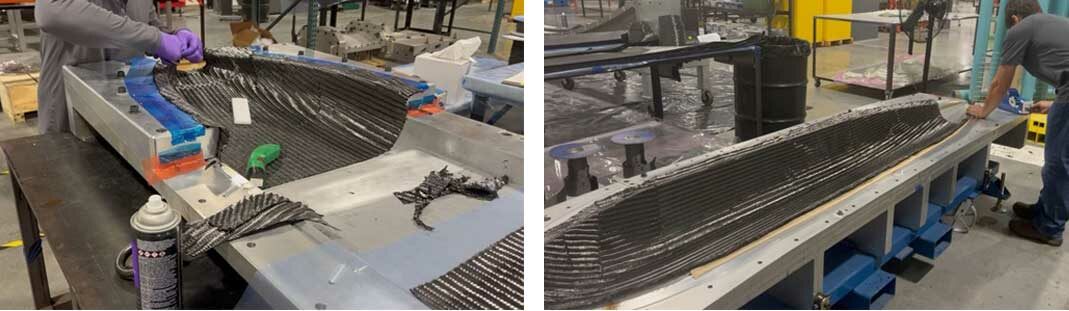

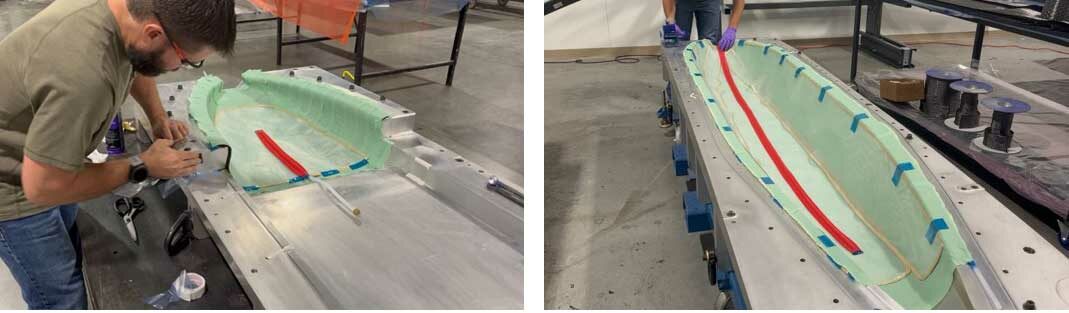

The upper and lower fuselage composite solution were manufactured using table cut Ply kits of QISO™ fabric that were hand applied and the resin infusion process was changed to VARTM. Operators hand applied the QISO™ kit into their respective outside mold line (OML), VARTM molds. The molds were machined to the final part OML plus coefficient of thermal expansion (CTE) scale factor offsets. After completion of the lay-up, a release ply, flow assist media, and a vacuum bag were installed on the backside of the laid up dry carbon fiber laminate. The epoxy resin was infused into the fiber using VARTM and the part was cured following the resin manufacturers recommendation. The cured fuselage sections were then cooled to room temperature and demolded from their respective VARTM molds and trimmed manually with excess to allow for final trim and drill to be completed using a 5-axis milling center.

Fuselage hand application of QISO™ broad goods fabrics into their VARTM molds for the fuselage composite solution.

Flow assist media placed onto the release liner before the vacuum bag is applied for the fuselage composite solution.

Demolding of the upper and lower fuselage composite solution.

RESULTS:

Use of hand applied, dry QISO™ carbon fabric, combined with VARTM infused epoxy resin, allowed Hawthorn Composites to meet Zone 5’s aggressive price and quality targets and the final solution achieved Zone 5’s expectations for reduced assembly and integration times on this fuselage composite solution.

Finished upper and lower fuselage composite solution

Share this Post