SWITCHING FROM METAL

The previous enclosure door was fabricated using metal, resulting in an overweight door that caused a tipping issue when the machine was being restocked and required additional counterbalance for safe operation. This made moving the machine difficult so an lighter weight alternative was sought.

CONVERTED COMPOSITE ENCLOSURE

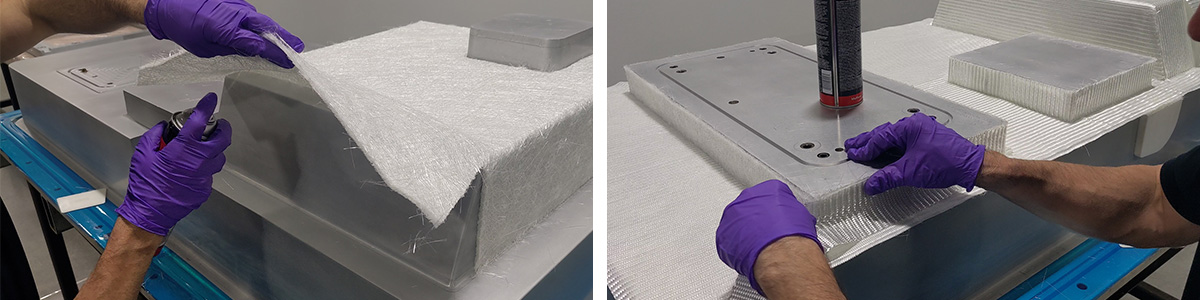

The customer required a composite solution that was a direct replacement for the metallic enclosure door, including access panels with no draft and minimal radii. To achieve the complex design, a resin transfer molding (RTM) tool was designed that would meet the dimensional requirements and allow for the use of low-cost raw materials. To drive down labor costs for composite kitting, an automated 20’ cutting table was used to accurately cut fabric following the unique ply kit pattern for process repeatability. To lower the labor requirement for lay-up a combination of thick (0.060”) chopped strand fiberglass and a thinner layer of fiber glass QISO™, a quasi-isotropic braided fiberglass fabric, were used. The 0.060” thick chopped fiberglass minimized layup labor.

Layup began on the male surface of the mold, starting with the chopped strand fiberglass mat, followed by a layer of the QISO fabric. Machined tooling inserts were placed into the mold during layup to ensure vertical flange walls with minimal draft angles for access panels were achieved. The layup process continued on all of the mold’s surfaces.

The outside edges of the composite enclosure were laid up using a layer of thick chopped fiberglass mat followed by an internal layer of balsa wood core, which helped to significantly lower the weight of the part, saving about 15lbs. The balsa wood was then followed by an outer layer of chopped strand fiberglass mat and a layer of QISO fiber glass to achieve the desired ½” wall thickness.

After layup was complete, the mold was closed using a single piece lid with O-ring seals. The mold was bolted closed and plumbed for infusion. The mold had multiple outlets to allow for control of the resin flow in the outlets to make sure no region of the part lacked proper resin infusion. The mold was placed into the oven, infused with resin, and cured to manufacture the composite enclosure door.

Once cure was complete, the mold was removed from the oven, the inlet tubes were removed, and the mold was opened in steps. The lid was removed first followed by the match tooling inserts, releasing the trapped parts of the composite and then the outer tooling was removed. After trimming, the composite enclosure door was complete and ready for painting.

RESULTS

The composite enclosure door was able to meet all geometric surface and stiffness requirements at only 32lb, less than 40% of the original 86lb metal enclosure door, while achieving customer price and performance targets. Converting to composite also meant the door would not sag overtime.

Watch a video of this case study or browse our of library of other case studies and applications. For more information on how Hawthorn Composites delivers high-value composites, click here.

Share this Post